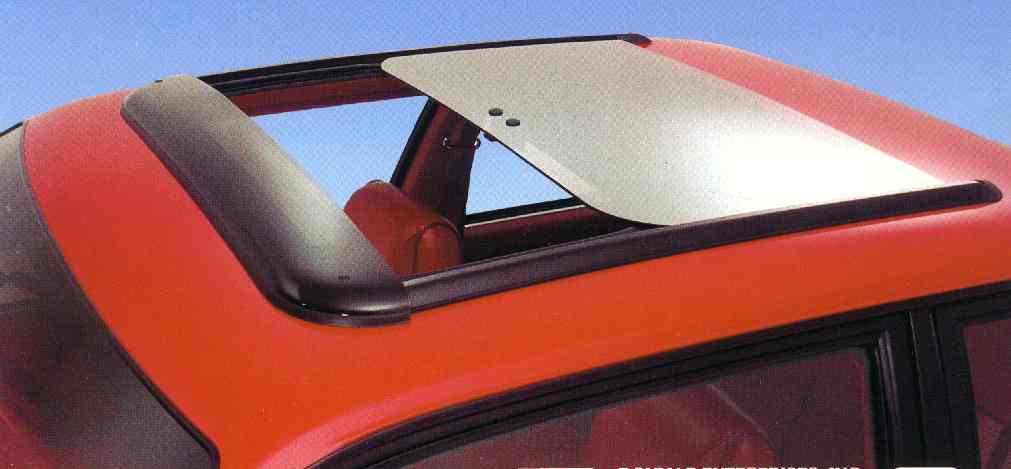

POP-UP Sunroofs

POP-UP Sunroofs were originally developed in the early 1970's as inexpensive, easy to install alternatives to inbuilt or folding fabric sunroofs. Early pop-ups were cumbersome to use, not very attractive and somewhat unreliable. Materials and manufacturing processes improved greatly since the early days, as did features and styling. First offered as a non-removable roof vents, many were even made of molded acrylic [bubbles] instead of glass, much like an architectural skylight. Because the basic design clamps firmly down upon the main seal, and the panel remains outside the vehicle, pop-ups are inherently watertight.

Quick-release removable glass became standard in the early 1980's, adding the convenience of full opening to the functional roof vent. Lever actuated latches evolved from single to multi-position for several levels of venting. Rotary [crank] latches provide infinite positions. Front hinges were a more complex engineering task, as they had to secure the front from opening, while allowing a pivot point and be easily released. The bayonette (or spoon) blade hinge provided a sliding rather than fixed pivot point. Other designs include a locking release hinge mechanism. One manufacturer even offered a front venting glass, which the front hinges lifted up as well! His-n-hers split panels included a central dome lamp.

Pop-ups were the earliest operable glass panel sunroofs, which created both the benefit and problem of added heat from extra sunlight. Ceramic printed patterns (dot matrix) blocked 5o-70% of the light transmission while still providing good visibility. Solar-reflective tinted glass looked better, but was not as effective as printed glass. High performance solar privacy glass was a huge innovation introduced in the early 1990's, as it blocked 60% more InfaRed (heat) and harmful UltraViolet light than standard solar reflective glass, while providing greater visibility. Other solutions include removable panel and intgrated roll-up sunshades.

Interior finish moved from sandwhiching the headliner with the metal clamping frame to variations of rigid and flexible trim finish rings or factory wrapped headliner finish for a true OEM look.

While the original pop-up frames (and many current models) were made of extruded aluminum, other technologies include cast aluminum and injection molded composite plastics. Framed glass or bonded hardware provide a seamless, smooth OEM look. Thinner glass, flusher finish, tight radius corners and a curved leading edge (bow front) were innovations in the late 1980's which greatly enhanced aftermarket sunroof styling [looking more OE], and helped them gain widespread acceptance by new car dealers.

SPOILER Sunroofs

![]()

SPOILER Sunroofs combine the basic design of a pop-up with a complex mechanism which allows the glass to both vent and slide open. Because the glass is only supported from the front edge in a cantilevered postion, it can't provide a 100% clear opening like other sliding sunroofs.Because the glass remains tilted, there is little wind noise due to turbulence hitting the rear edge of the hold -the glass acts like a spoiler, smoothly routing the air flow over top. Early spoiler sunroofs were not much more than front venting crank operated pop-ups, providing barely a 40% clear opening, making them an expensive alternative with little additional benefit as the pop-up glass could simply be removed to provide a full opening. Newer designs yield nearly 80% clear, and the self storing panel is easier to deal with. For short roof vehicles, a spoiler is often the only sliding sunroof solution.

The first factory spoiler sunroofs appeared in the Honda CRX and Mazda RX7 as metal panels. The lighter weight allowed a longer cantilever and yielded a larger percentage opening than equivalent sized glass panels. The first Saturn cars included a very large glass spoiler roof with integral sliding shade. While this still did not provide a larger percentage opening, the very deep glass provided a reasonable size clear opening while the headliner masked off the cantilevered glass which would otherwise intrude into the opening. These 3 vehicles greatly improved the aftermarket sales potential as they provided market familiarity.

Electric motors [for power operation instead of the manual crank] first arrived as an adaptation with add-on motor boxes. Integral motors, along with larger percentage openings helped aftermarket spoilers become a mainstay in every sunroof shop. This category of sunroofs offers a wider range of features an options than any other. Basic models include a flexible trim bezel for quick-fit exposed ring installation, while deluxe models are designed to be wrap finished for an OEM interior look. Shade options range from removable panels to twin or full width integrated roll-up, multi-stop rollo, and even hard panel sliding shade systems. Most feature high performance glass. Some offer electronic control for express open/close and auto-close. Self-deploy wind deflectors pop-up when the glass opens. Telescoping drive mechanisms enabled the glass to open even farther, providing the largest percentage openings. Spoilers remain the most versatile and growing market segment in both OEM and aftermarket channels.

INBUILT Sunroofs

INBUILT Sunroofs (internal sliding; moonroofs). When closed, the sunroof panel is flush with the roofskin, and when open, it retracts between the roof and headliner. Inbuilts require a water management system [catch tray and drain tubes] to channel away any water which could seep through the perimeter seal and any standing water left on the panel when opened.

Since the early 1950's, inbuilts were metal panels, painted to match the roof, with a welded-in substructure where the panel retracts and stores. The glass panel was a huge innovation in the mid 1970's, which also included the development of an integral sliding shade. Inbuilt technology in the 1980's expanded to include a venting feature, self-deploy wind deflectors, single touch express open/close and bonded installation, which dramatically reduced installation time and eliminated welding. The kits have also gotten lighter and thinner, reducing headroom encroachment. As factory headliners moved from suspended cloth to hard board, new developments in aftermarket kits include a headliner substrate to blend the interior for a factory finished look.

Enhanced electronic control adds features including programmable preset positions, safety auto reverse and auto-close on ignition off to express open/close. Optional rain sensors can be installed which detect moisture and will close the sunroof even if the vehicle is left unattended, so the sunroof may be left vented or open in the parking lot all day without concern for getting wet.

FOLDING Sunroofs

FOLDING Sunroofs are perhaps the original sunroof, which evolved from a simple removable tarp to a complex self storing integrated mechanism with bows to support the large fabric span. Part convertible top and part sliding sunroof, folding sunroofs can provide a much larger clear opening than other sunroofs. While designed to be weathertight, they aren't as watertight as rigid panel sunroofs due to the difficulty in forming a fixed perimeter seal with a flexible fabric panel.

Renault's LeCar and Suzuki's Sidekick had framed fabric panel which simply folded back over the roof when open, and had to be snapped down when closed. Citroen's 2CV was famous for its canvas roof which rolled back like a sardine can. The classic original VW Beetle offered perhaps the most recognized folding sunroof.

Originally manually operated with a separate mechanism to lock closed and stretch the cover taught, a cam-lock latch enabled easy one-hand operation. More modern enhancements include powered, cable driven systems. Folding with combination front and rear openings have been produced, but never sold widespread. Popular in Europe for decades as the "poor man's convertible", folding sunroofs never gained strength in North America. Few folding sunroofs are still produced or available today for aftermarket or OE programs, as well as frequently showing up in concept cars.

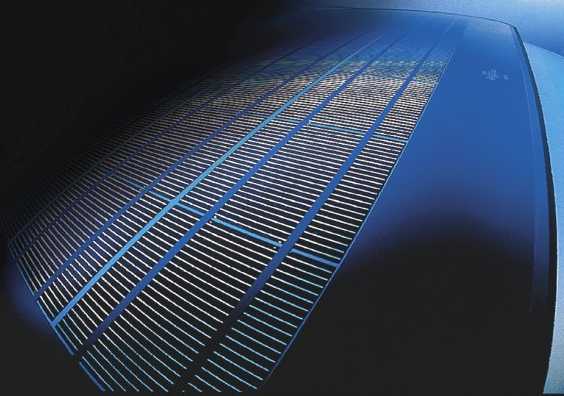

TOP-MOUNT SLIDING Sunroofs

TOP-MOUNT SLIDING Sunroofs (rail mount topsliders) originally combined the low cost and easy installation of a pop-up with the self-storing glass and full sunroof opening of an inbuilt. Because the entire mechanism is external, installation does not take any interior headroom. The glass is fully supported in the track, allowing it to provide a very large opening.

The basic design is watertight, as the main seal is elevated well above the roof and water doesn't flow uphill! Any standing water on the glass remains outside the vehicle, to blow off in the wind. Thus, a fully retracting sunroof can be made without the need for drain tubes.

Due to the fact that top-mount sliders sit above the roof, most include integral wind deflectors to both finish the leading edge and smoothly deflect the airflow over the raised frame and opening. Topsliders never gained widespread acceptance in North America due to the unfamiliar styling of the raised rails on the roof. Popularity in Europe came from a Renault factory topslider, which featured a pneumatic main seal. The seal was deflated to allow the glass to slide freely in the track without friction from the main seal, and ensured a watertight seal when closed and inflated. In the late 1970's, there was a top-mount slider made with a polyurethane frame, which was painted to match the car [Chevrolet used this on the Monza].

Originally, these were glass panels with no mechanism other than the latch/handle - the glass was manually moved open or closed within a roof mounted channel. Over time, short rail versions [partially supported, cantilevered glass], complex multi-position locking mechanisms, and cable-drive mechanisms (manual and electric) were developed.

At the OEM level, topslider designs often use a flush, integrated roof track, like the BMW Mini, or one integrated into the body seam, like the Toyota Previa. Current models lift the glass off the main seal while open, and drop back down on it when closing to seal. Topsliders are most likely to be seen in panoramic roof systems today.

PANORAMIC ROOF SYSTEMS

![Louvered Panoramic Sunroof [Webasto Lamella]](http://www.sunroofs.org/Tech/Lamella4.jpg)

PANORAMIC ROOF SYSTEMS are a new type of large or multi panel sunroofs which offer a view of the sky and even openings above both the front and rear seats. These may combine both operable and fixed glass panels. Large operable openings are often accomplished with top-mount slider or spoiler type mechanisms. Familiar factory options include the BMW Mini, Audi A3 wagon, Caddilac SRX, Scion tC, Mercedes C230, Mercedes ML430 and Pontiac G6. From louvered metal or glass to multi-panel fixed and operable glass systems, factory and aftermarket options provide the greatest opening and widest view of any sunroof option.

REMOVABLE ROOF PANELS

REMOVABLE ROOF PANELS (T-tops & Targa roofs) open the entire vehicle roof to the side windows and typically must be removed to enjoy the openair. Most are not self storing, although some concepts include that option. The first removable roof systems were an opaque panel, often vinyl covered or textured black plastic, such as the Porsche 914 Targa . Translucent or transparent acrylic and glass panels were first featured on the Corvettes in the early 1970's. Technology has changed little, although locking systems, shade panels and various material imporvements have deveolped over time. One aftermarket supplier made a rear venting T-top.The latest Porsche has a panoramic sliding glass which looks more like a targa, and stores inside the rear windshield. T and targa roof systems are now relegated to specialty customs and super performance or exotic vehicles.

--------------------------------------------------------

What's new on the horizon in sunroof technology?

OEM Fixed Glass Panoramic Roof Systems

Aftermarket Fixed Glass Panoramic Roof Systems

Fixed Glass Panels provide a view of the sky, without the complexity or added weight of a large sunroof with an operable mechanism. Often these combine an operable sunroof in front with one or more fixed panels in the back. OE options include the Chevrolet Malibu Maxx, Jeep Commander, Nissan Maxima and Quest. There is a new aftermarket option for the Ford Mustang (GlassBack) which converts the entire roof sheet metal to a fixed glass panel.

Oversized Inbuilts are enormous sunroofs now being offered in vehicles like the Hummer H2, H3, and Subaru Outback.

Electrochromatic variable intensity glass which allows the panel adjust from transparent to opaque, will make very large fixed or operable glass panels viable without adversely effecting passenger compartment temperature or interior fading and eliminate the the need for shade systems. High performance (solar privacy) and metalized laminated glass include heat rejecting properties with ultra low UV transmission while maintaining good visibility.

Solar Collectors integrated into the sunroof glass have been around nearly 15 years, but due to the cost, have yet to gain much market popularity. Several European luxury models now offer this feature. The solar collectors may be used to trickle charge the vehicle battery, run the vehicles A/C fan, or even power integrated ventilations fan to cool the interior.

Today's sunroofs provide a greater range of features and options than ever before, and technology is ever advancing to provide the next best thing. Surely as vehicles evolve for the future, so will sunroof systems, and enthusiasts love for riding the open road with the wind in their hair and sun on their face.

SUNROOFS.ORG history & Technology copyright June 2006

written by M. Levinson

Copyright 2006-2023, all rights reserved.